Different Types Of Polycarboxylate Superplasticizers Performance Comparison

Blog Different Types Of P

Blog

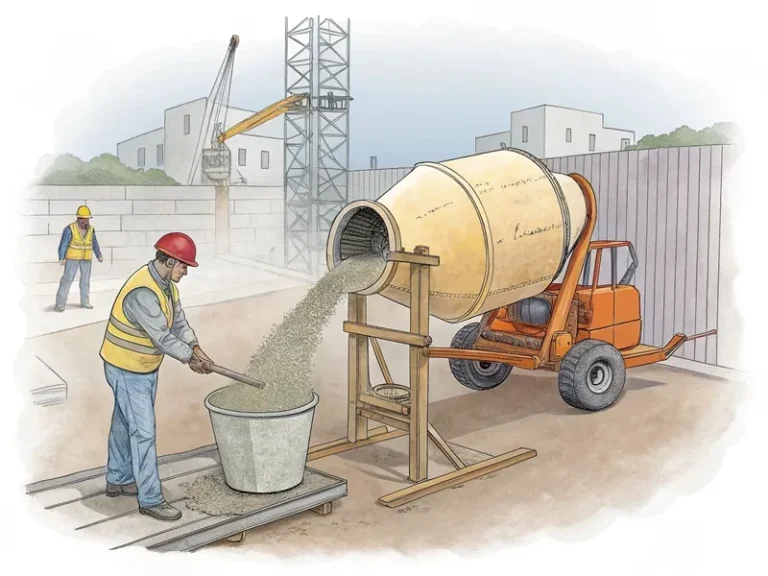

Concrete has become one of the most widely used building materials worldwide due to its strength, durability, and versatility. However, achieving higher strength in concrete typically requires specialized additives. These additives are crucial for improving concrete’s compressive and tensile strength, especially in demanding construction projects.

This article will explore the role, types, benefits, and applications of admixtures to increase strength of concrete.

The strength of concrete is crucial for its performance in construction. Although traditional methods, such as adjusting the water-cement ratio and optimizing the mix design, can improve strength, the use of additives brings more benefits:

Higher load-bearing capacity: Stronger concrete can withstand greater loads, making it an ideal choice for high-rise buildings, bridges, and industrial structures.

Reduce material usage: Achieve higher strength with less cement, making the mixture more cost-effective and sustainable.

Faster construction: Accelerating the use of admixtures can quickly improve strength and shorten construction time.

Improve durability: Reinforced concrete can better resist environmental pressures such as freeze-thaw cycles, chemical erosion, and wear.

Cost-effectiveness: Reduce the demand for high cement content while maintaining or improving strength

Superplasticizer, also known as high-efficiency water-reducing agents, reduces the water content in the mixture while maintaining workability, thereby improving strength and durability.

By reducing the water-cement ratio, superplasticizers can achieve a denser and more compact microstructure with fewer pores, thereby improving compressive and tensile strength.

A lower water-cement ratio is directly related to higher strength. For example, reducing the water-cement ratio from 0.5 to 0.4 can significantly improve the 28-day compressive strength of concrete, typically up to 20-30%. This strength gain is crucial for applications where concrete must withstand heavy loads, such as in the construction of multi-story buildings or large-span bridges.

Silicon powder is a mineral admixture that can significantly improve the strength and durability of concrete. It is a byproduct of silicon or ferrosilicon production and is known for its ultrafine particles.

During the hydration process, silicon powder reacts with calcium hydroxide to form additional calcium silicate hydrate (C-S-H), which is responsible for the strength of concrete. Silicon powder-reinforced concrete can achieve high compressive strength, typically exceeding 100 MPa. This makes it suitable for applications that require ultra-high strength, such as the construction of prestressed concrete components or structures exposed to harsh chemical environments.

Volcanic ash materials, such as fly ash and ground blast furnace slag (GGBS), enhance the strength of concrete by reacting with lime to form additional C-S-H.

When volcanic ash is added to concrete, it not only replaces a portion of cement, reducing the cost of the mixture, but it also helps to improve strength over time.

This admixture are used to accelerate concrete’s solidification and hardening process, which helps to develop early strength.

Early strength agent work by promoting cement hydration. In cold weather, the normal hydration process of cement can be significantly slowed down, but accelerating admixtures can help concrete reach the required strength faster and reduce the risk of damage due to freezing.

Fibers can be added to concrete to enhance its tensile strength and toughness, which is crucial for preventing cracking and improving its overall strength performance.

The commonly used fibre types in concrete include steel, polypropylene, and basalt fibre.

Steel fibres are very effective in improving the tensile strength of concrete, which can enhance its post-cracking strength and enable it to withstand higher loads even after the crack begins.

Polypropylene fibres reinforce cracks and distribute stress within the concrete matrix. On the other hand, polypropylene fibres are lightweight and mainly used to prevent plastic shrinkage cracking in the early stages of concrete solidification.

Basalt fibre has good mechanical properties, high-temperature resistance, and chemical corrosion resistance.

To maximize the benefits of additives, the following best practices must be followed:

Optimize mix design: Ensure a balanced water-cement ratio and appropriate aggregate grading.

Choose appropriate additives based on the specific strength requirements, environmental conditions, and project schedule.

Follow the manufacturer’s guidelines: follow the recommended dosage and mixing procedure for the selected admixture.

Test mixture: Conduct trial mixing to evaluate the performance of the mixture and ensure compatibility with other materials.

Monitoring maintenance conditions: Proper maintenance is crucial for achieving the required strength of concrete.

Skyscrapers and high-rise buildings: High-strength concrete is crucial for supporting the enormous loads on high-rise structures.

Bridges and overpasses: Reinforced concrete ensures durability and resistance to heavy traffic loads.

Industrial flooring: Enhanced strength can resist wear and heavy machinery.

Marine structures: High-strength concrete has lower permeability and is more resistant to chloride erosion and corrosion.

The use of admixtures to improve the strength of concrete is a crucial step in modern construction. Admixtures can make the structure stronger, more durable, and more cost-effective. Whether you work in high-rise buildings, bridges, or industrial facilities, choosing the appropriate admixture, such as superplasticizers, silica fume, or volcanic ash materials, it can significantly improve the performance of concrete mixtures.

Different Types Of Polycarboxylate Superplasticizers Performance Comparison

Blog Different Types Of P

Super Early Strength Polycarboxylate Superplasticizer For Sleeve Grouting Material

Blog Super Early Strength