Study on performance of new carboxylic grafted polymer high efficiency slump retaining agent

Blog Study on performance

Blog

Abstract: In modern construction projects, concrete, as a widely used building material, has a direct impact on the quality and life of the building due to its performance. With the continuous development of construction technology and the increasing demand for concrete performance, polycarboxylate superplasticizers have also experienced constant growth and innovation.

Polycarboxylate Superplasticizer is a high-performance water-reducing agent that integrates the functions of water reduction, shrinkage, enhancement, anti-slumping, and environmental protection. It is also a cement dispersant in cement concrete.

This synthetic polymer is added to concrete and dry mortar mixtures to improve workability, reduce water content, and increase strength and durability. It is widely used in highways, bridges, dams, tunnels, high-rise buildings, and other projects.

Polycarboxylate superplasticizers is a macromolecule polymer copolymerized with unsaturated monomers containing a carboxyl group and other active monomers.

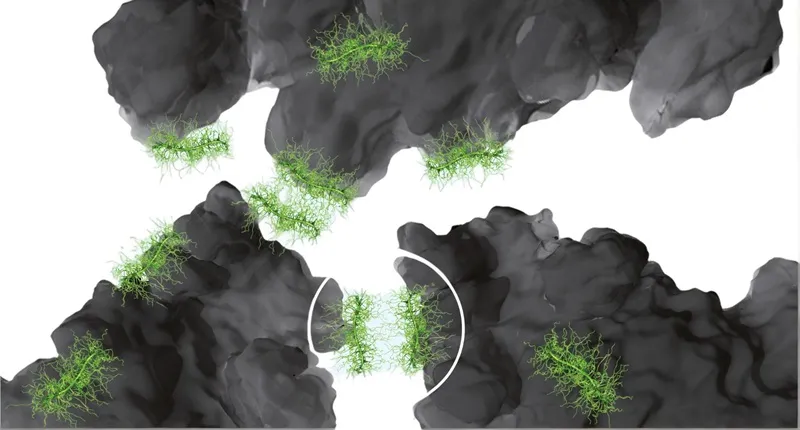

It adsorbs on the surface of cement particles, generating electrostatic repulsion and a spatial resistance effect. The electrostatic repulsion makes the cement particles repel each other.

At the same time, the spatial resistance effect prevents the cement particles from regrouping, thus dispersing them, releasing the water wrapped in them, and increasing the fluidity of concrete.

Generally, the water reduction rate of the polycarboxylate superplasticizers can reach 25%—40% or even higher, which can significantly reduce the water-cement ratio of concrete and improve its strength and durability.

It can keep the slump of concrete unchanged for a certain period, which is very important for long-distance transportation and long-time construction of concrete projects.

In the 1930s, lignosulfonate was developed as a water-reducing agent, but it had limitations, such as a low water reduction rate. Subsequently, naphthalene-based water-reducing agents and melamine water-reducing agents appeared one after another.

Although there was some progress in performance, there were still problems, such as adaptability to cement and environmental pollution.

With the development of polymer chemical technology in the 1980s, the concept of polycarboxylic acid as a water-reducing agent appeared.

Researchers conducted preliminary research on its synthesis method and basic performance and found that it has a unique molecular structure and performance advantages.

However, the synthesis process is complicated, and the production cost is high, which limits its large-scale application.

From the 1990s to the beginning of the 21st century, the performance of Polycarboxylate superplasticizers improved, and the cost was reduced by optimizing the selection of monomer and polymerization reaction conditions.

Its application field gradually expanded from high-performance concrete, self-compacting concrete, and other special projects to some ordinary concrete projects.

In the 21st century, Polycarboxylate superplasticizers have been widely recognized and commercially used in high-performance concrete, especially in applications requiring high strength and workability.

Due to strict environmental requirements, PCE superplasticizer have become more popular because of their environmentally friendly characteristics. The production technology is mature, and the product quality is stable.

The PCE superplasticizer molecular structure and mass can be adjusted and controlled.

Therefore, the molecular structure can be adjusted by changing the ratio of a carboxyl group and ether group or carboxyl group and ester group or introducing functional groups such as amino group, sulfonic acid group, phosphoric acid group, and other functional groups on the main chain of the water reducing agent, to increase the dispersing performance of polycarboxylic acid water reducing agent by adjusting the molecular mass, the ratio and length of main and side chains, and to improve its adaptability.

Most of the Polycarboxylate superplasticizers are prepared by the free radical polymerization process, the reaction temperature is 60-80℃, and the synthesis process needs heating, which is not only a complicated process but also requires the burning of coal for heating, which will consume energy and bring environmental pollution problems.

So the synthesis of polycarboxylic acid water reducing agents at room temperature through redox system is the direction of the development in the future;

PCE powder is more convenient than PCE liquid because of transportation and use, so the powder PCE superplasticizer will also be the future development trend.

With the continuous changes in concrete raw materials, different seasons, and construction conditions, the performance requirements for polycarboxylate superplasticizers are becoming increasingly stringent.

The systematic development of functional polycarboxylate superplasticizer products is the focus of future growth.

With the continuous deterioration of concrete raw materials, the slump retention of concrete is getting more and more attention, so the polycarboxylic acid water-reducing agent with a slump-proof function is a crucial product to be developed in the future

The low-temperature environment in winter will slow down the hydration of cement, which makes the early strength of concrete develop slowly, thus restricting the application of PCE in some construction projects.

Therefore, the concrete in the future urgently needs the PCE with high early strength, which is another critical product in the development of the future.

With the continuous expansion of construction scale, the natural sand and gravel are constantly being mined and used, the sand and gravel with excellent performance and stable quality are less and less, and a large number of sand and gravel are with different degrees of clay, which seriously affects the ease and durability of concrete after being mixed into the concrete.

Therefore, PCE superplasticizer with anti-mud performance is urgently needed in the concrete market now, and also a key trend for the development in the future.

According to the PCE superplasticizer market research report published by “Global Market Monitor”, the global PCE superplasticizer market size reaches 8,363 million (USD) by 2023, with the Chinese market at 2,673 million (USD).

The report combines the global economic policy situation and market dynamics to make a reasonable forecast for the global PCE superplasticizer market, which is expected to reach 12.733 billion (USD) by 2029, growing at a CAGR of 7.25%.

The height of both buildings exceeds 600m.

In the construction of the Burj Khalifa, the use of polycarboxylate superplasticizer allowed the concrete to be pumped to a height of more than 600 meters in one uninterrupted operation. This admixture played an essential role by reducing the amount of water used and improving the strength and fluidity of the concrete.

In the foundation construction of the Shanghai Tower, polycarboxylate superplasticizer supported the project to set a world record by pouring 61,000 cubic meters of concrete in one go within 60 hours. The large-scale concrete pouring was completed quickly, which ensured the smooth progress of the project.

The development of polycarboxylate superplasticizer in concrete has gone through many stages; from early exploration to today’s wide application, its performance is constantly optimized, and its application field is continuously expanded.

It plays an irreplaceable role in improving the performance of concrete, promoting the progress of concrete technology, and meeting the needs of construction projects.

With the continuous improvement of science and technology, PCE superplasticizer will develop in the direction of high performance, multifunctionality, and green environmental protection in the future, bringing more advantages and value to concrete projects.

Study on performance of new carboxylic grafted polymer high efficiency slump retaining agent

Blog Study on performance

Preparation Of Slow Release And Slump Retaining Polycarboxylate Superplasticizer

Blog Preparation of slow

Different Types Of Polycarboxylate Superplasticizers Performance Comparison

Blog Different Types Of P