Super Early Strength Polycarboxylate Superplasticizer For Sleeve Grouting Material

Blog Super Early Strength

Blog

In the constantly developing field of building materials, high-efficiency water-reducing agents for concrete have completely changed the production method of high-performance concrete. Among the various components that affect the effectiveness of high-efficiency water-reducing agents, monomer TPEG (tert butyl polyethylene glycol) is a key component. This article aims to explore in depth what TPEG is, its role in concrete superplasticizers, its unique properties, applications, and future trends related to it.

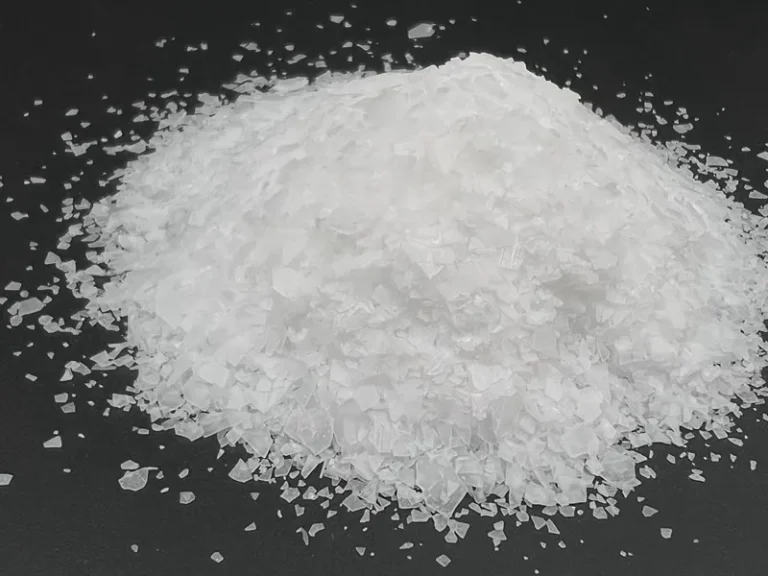

TPEG( ter-butyl Polyethylene Glycol) is a large molecular monomer widely used in the synthesis of polycarboxylate-based high-efficiency water-reducing agents, which are important additives for modern concrete. Structurally speaking, TPEG has a unique T-shaped structure. It consists of a skeleton with terminal double bonds and long polyoxyethylene side chains extending from the skeleton, and the terminal double bonds are crucial for its participation in polymerization reactions. The side chains of polyethylene oxide are usually composed of repeated ethylene oxide units, and the length of these chains can vary, which in turn affects the performance of the final superplasticizer product.

The molecular structure of TPEG endows it with unique characteristics, making it highly suitable for the production of high-efficiency water-reducing agents. The presence of polyoxyethylene side chains provides excellent hydrophilicity. At the same time, the terminal double bond allows it to copolymerize with other monomers, such as acrylic acid, forming polycarboxylate ether polymers with specific molecular structures.

The production of TPEG-based high-efficiency water-reducing agents usually involves a series of chemical reactions. Firstly, TPEG is synthesized by reacting allyl alcohol or other suitable raw materials with ethylene oxide under specific catalytic conditions to form T-shaped polyoxyethylene ether monomers.

Subsequently, TPEG copolymerizes with other monomers (such as acrylic acid) in the presence of initiators, typically free radical initiators such as potassium persulfate or azobisisobutyronitrile. The reaction is carried out in a liquid medium, and the reaction conditions, including temperature, reaction time, and monomer ratio, are carefully controlled to obtain superplasticizers with the desired properties.

TPEG has high reactivity due to its terminal double bond. This enables it to easily participate in copolymerization reactions under appropriate conditions, such as the presence of initiators and specific temperatures. The ability to copolymerize with other monomers precisely controls the molecular weight, molecular structure, and functional group distribution of the resulting polycarboxylate ether superplasticizer.

This high reactivity allows the performance of superplasticizers to be customized to meet the different requirements of different concrete applications.

Due to its long polyoxyethylene side chains, TPEG exhibits excellent hydrophilicity. This characteristic is crucial for its role in high-efficiency water-reducing agents, as it enables polycarboxylate ether polymers to effectively interact with the water phase in concrete mixtures.

The hydrophilicity of TPEG facilitates the adsorption of high-efficiency water-reducing agent molecules onto the surface of cement particles, as well as the stability of cement particles dispersed in water, thereby improving the overall performance of high-efficiency water-reducing agents.

TPEG has good compatibility with various other monomers and materials used in the synthesis of high-efficiency water reducing agents. It can copolymerize with monomers such as acrylic acid, maleic anhydride, and itaconic acid to produce polycarboxylate ether superplasticizers with different properties.

In addition, TPEG-based high-efficiency water-reducing agents typically have good compatibility with various types of cement, including ordinary Portland cement, Portland blast furnace slag cement, and Portland fly ash cement. This compatibility ensures that TPEG-derived high-efficiency water-reducing agents can be used in various concrete formulations without causing adverse reactions or performance issues.

TPEG is widely used in the production of high-performance concrete (HPC) that requires excellent strength and durability. Its ability to improve fluidity while maintaining low moisture content makes it an ideal choice for demanding construction projects.

In the application of precast concrete, precision and quality are crucial, and TPEG can improve the workability of the mixture, ensure uniformity, and reduce the risk of defects.

TPEG is a key component for self compacting concrete (SCC) that can flow and fill molds without mechanical vibration. Its characteristics ensure that concrete achieves a smooth surface with minimal effort.

The use of TPEG as a high-performance water-reducing agent monomer for concrete represents a significant advancement in concrete technology. Its ability to enhance processability, reduce moisture content, and improve overall performance makes it a valuable asset in the construction industry. With the increasing demand for high-strength and durable concrete, adding TPEG to concrete formulations will play a key role in addressing these challenges.

Super Early Strength Polycarboxylate Superplasticizer For Sleeve Grouting Material

Blog Super Early Strength