Super Early Strength Polycarboxylate Superplasticizer For Sleeve Grouting Material

Blog Super Early Strength

Blog

Abstract: As a high-performance polyether monomer, HPEG 2400 plays a key role in improving the durability of concrete. Its application provides a strong guarantee for the long-term service of concrete structures in complex environments, which helps to reduce maintenance costs, extend the service life of buildings, and promote the development of the construction industry in a more sustainable direction.

HPEG 2400, methyl allyl alcohol polyoxyethylene ether, is a kind of polyether with a specific chemical structure, polycarboxylate superplasticizer raw materials. Its molecular structure contains methyl allyl and polyoxyethylene ether chain segments, and this unique structure gives it many excellent properties.

Methyl allyl provides specific reactivity, which enables it to participate in the synthesis reaction of a polycarboxylic acid water-reducing agent. At the same time, the polyoxyethylene ether chain segment brings good water solubility and spatial site resistance effect, which are essential in enhancing the durability of concrete.

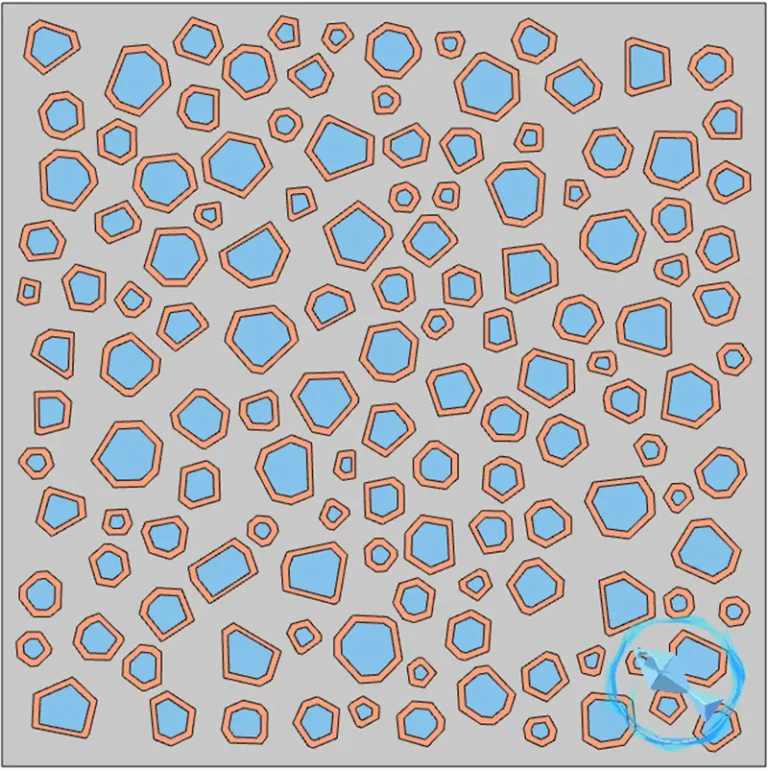

The dispersing effect of HPEG 2400 in concrete helps to optimize the pore structure of concrete. It can make the cement particles evenly dispersed, reduce the formation of large holes and connecting holes, and increase the proportion of small holes and gel holes.

These tiny pores and gel pores can effectively prevent the penetration of water, harmful gases and ions, thus improving the impermeability of concrete. In underground projects, water conservancy projects and other projects that require high impermeability of concrete, the use of concrete containing HPEG 2400 can effectively prevent the leakage of groundwater and protect the integrity of the structure.

HPEG 2400 can improve the structure of the interfacial transition zone between cement paste and aggregate. In concrete, the interfacial transition zone is often a weak link, prone to the formation of pores and micro-cracks, leading to the intrusion of water and harmful substances.

HPEG 2400, through its molecular structure of the polyoxyethylene ether chain segment and the surface of the cement particles and aggregates in the physical and chemical interaction, enhances the compactness of the interfacial transition zone, reduces the porosity, and further improves the seepage resistance of concrete.

HPEG 2400 has a specific air-entraining effect in concrete. It can introduce uniformly distributed tiny air bubbles in the process of concrete mixing, and these air bubbles form disconnected pore structures after concrete hardening.

When the concrete is subjected to freeze-thaw cycles, these pores can provide space for the growth of ice crystals and relieve the destructive stress on the concrete structure caused by the expansion of ice crystals, thus improving the frost resistance of concrete.

In construction and road projects in cold regions, the improvement of frost resistance is essential to ensure the everyday use and long-term stability of concrete structures in winter.

In addition, hydrogen bonding between the oxygen atoms in the molecule of HPEG 2400 and the water molecules lowers the freezing point of the aqueous solution in concrete. The water in the concrete is less likely to freeze at low temperatures, which reduces the damage to the internal structure of the concrete caused by freeze-thaw cycles and further enhances the frost resistance of the concrete.

By optimizing the microstructure of concrete, HPEG 2400 makes it more dense, thus hindering the diffusion of carbon dioxide into the concrete interior. Carbonation of concrete is the chemical reaction between carbon dioxide and alkaline substances such as calcium hydroxide in the hydration products of cement.

Carbonation will lead to the reduction of the alkalinity of concrete. Reinforcement will lose alkaline protection and be rusted easily. The dense structure formed by HPEG 2400 reduces the chances of carbon dioxide contacting with the alkaline substances inside the concrete, which slows down the process of carbonation and improves the anti-carbonation property of concrete.

At the same time, HPEG 2400 helps to maintain the alkaline environment inside the concrete. It can inhibit the decomposition and consumption of cement hydration products to a certain extent and keep the pH value inside the concrete relatively stable so as to provide stable alkaline protection for the steel reinforcement, preventing the corrosion of the steel reinforcement and indirectly improving the overall durability of the concrete.

When the alkaline substances in concrete (such as potassium hydroxide, sodium hydroxide, etc.) and the active ingredients in aggregates (such as some siliceous aggregates) undergo a chemical reaction, expansion products will be generated, resulting in expansion stress inside the concrete, which will lead to cracking, spalling and other damages to the concrete.

Such damage will not only reduce the strength and appearance quality of concrete but also seriously affect the safety and durability of concrete structures.

HPEG 2400 can inhibit the occurrence of alkali-aggregate reactions to a certain extent. The polyoxyethylene ether chain segment in its molecular structure can physically adsorb or chemically react with alkaline substances in concrete, reducing the contact between alkaline substances and aggregate, thus reducing the activity of alkaline-aggregate reaction.

At the same time, the addition of HPEG 2400 can also improve the microstructure of concrete, increase the compactness of concrete, further enhance the resistance of concrete to alkali-aggregate reaction and protect the concrete structure from damage caused by internal expansion stress.

Reinforcing steel is a vital stress component in reinforced concrete structures, and its corrosion will lead to a reduction in the cross-section and strength of reinforcing steel.

At the same time, the volumetric expansion of corrosion products will cause the concrete protective layer to crack and spall off, further accelerating the corrosion of reinforcing steel and the destruction of the concrete structure. Therefore, it is crucial to enhance the corrosion resistance of steel reinforcement to improve the durability of concrete structures.

HPEG 2400 effectively prevents the penetration of external moisture, oxygen and aggressive ions (e.g., chloride ions) into the interior of the concrete by improving the compactness and impermeability of the concrete, thus providing a relatively stable alkaline environment for the steel reinforcement and inhibiting the corrosion of the steel reinforcement.

In addition, HPEG 2400 may also form a protective film on the surface of the reinforcement, further isolating the reinforcement from contact with external aggressive substances, slowing down the corrosion of the reinforcement and extending the service life of the reinforced concrete structure.

HPEG 2400, as a key polyether monomer, is of non-negligible importance in enhancing the durability of concrete. It enhances the durability of concrete through various mechanisms, including improving impermeability, frost resistance, carbonation resistance, inhibiting alkali-aggregate reaction, and enhancing the corrosion resistance of reinforcing steel, which provides strong support for the long-term and stable service of concrete structures in various complex environments.

In many actual projects, the use of HPEG 2400 significantly extends the service life of buildings, reduces maintenance and repair work, and brings significant economic and social benefits.

Super Early Strength Polycarboxylate Superplasticizer For Sleeve Grouting Material

Blog Super Early Strength