Super Early Strength Polycarboxylate Superplasticizer For Sleeve Grouting Material

Blog Super Early Strength

Blog

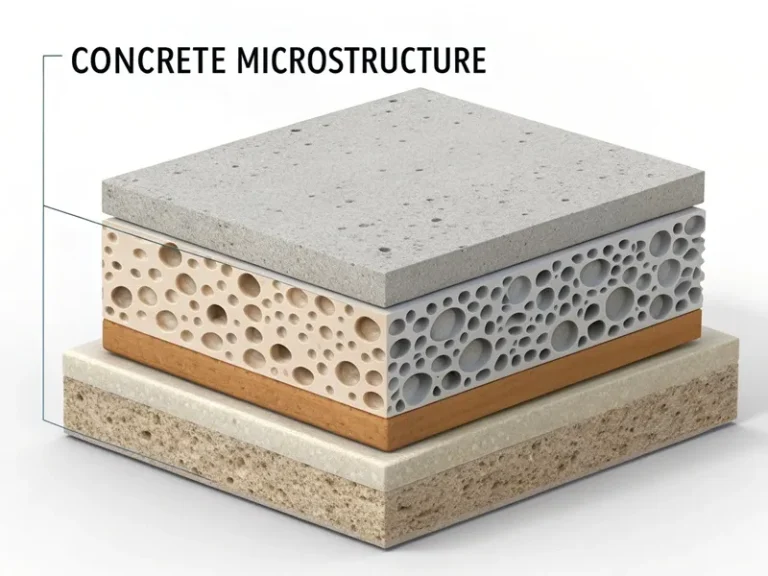

Concrete, as the most widely used building material in the world, is not only determined by macroscopic mechanical indicators, but also by its internal microstructure at a deeper level. As a key additive in modern high-performance concrete, polycarboxylate superplasticizer (PCE) not only significantly improves concrete performance during construction, but also fundamentally optimizes its mechanical and durability properties by regulating its microstructure.

To understand the influence of PCE on the microstructure of concrete, it is necessary first to understand its core mechanism of action:

Efficient dispersion effect: PCE molecules have a unique comb-like structure, with the main chain adsorbed to the surface of cement particles and the side chains extending into water, resulting in substantial steric hindrance and electrostatic repulsion. This enables the originally agglomerated cement particles to be efficiently dispersed, releasing the water trapped within the agglomerates and thereby significantly reducing the amount of mixing water required.

Reducing the water-cement ratio (W/C): This is the fundamental influence of PCE on the microstructure. PCE allows concrete to be mixed at lower water-cement ratios while maintaining or even improving fluidity.

PCE has the following key effects on the microstructure of concrete through its unique mechanism of action:

Reducing porosity: Lowering the water-cement ratio directly means reducing the amount of water used in the mixing process. When these waters are consumed or evaporated during the hydration process, the number of pores (especially capillary pores) left behind will be significantly reduced. The efficient dispersion of PCE also makes the distribution of cement particles more uniform, reducing the formation of larger voids caused by agglomeration.

The application of PCE not only reduces total porosity but also shifts the remaining pore-size distribution toward more petite sizes.

Impact: Lower porosity and a narrower pore-size distribution mean the concrete interior is denser, with fewer connected pores, significantly reducing permeability and improving resistance to freeze-thaw and chloride-ion erosion.

Densification of C-S-H gel: cement hydration mainly generates hydrated calcium silicate gel (C-S-H). PCE efficiently disperses cement particles, enabling hydration reactions to proceed more fully and uniformly. As a result, the C-S-H gel formed is more compact and uniform, with better filling effect and fewer internal defects.

Under the action of PCE, the growth morphology and size of hydration products (such as calcium hydroxide crystals) may also be affected, tending to form smaller, more evenly distributed crystals, thereby avoiding the formation of large, defect-prone crystals.

Effect: The more dense and uniform C-S-H gel is the primary source of concrete strength. Improving the morphology of hydration products directly enhances the strength and durability of concrete.

The concept of the interface transition zone (ITZ): a weak region between the aggregate surface and the cement slurry. Due to the high “wall effect” and the local water-cement ratio, ITZ is usually looser and has larger pores than the main cement paste, making it a weak link in concrete performance.

The optimization function of PCE:

Tight packing of cement particles: PCE enables cement particles to be packed more tightly and evenly on the aggregate surface, reducing the thickness of the water film near the aggregate surface.

Optimization of hydration products: the cement in the ITZ area is more fully hydrated, the C-S-H gel formed is denser, and the calcium hydroxide crystals are finer.

Impact: After optimization, the porosity of the ITZ area decreases, the density increases, and the bonding strength between the aggregate and cement slurry is significantly enhanced, thereby comprehensively improving the overall strength, toughness, and durability of the concrete.

The positive effects of PCE on the microstructure of concrete ultimately manifest in a significant improvement in macroscopic performance:

High strength: lower porosity, a more compact C-S-H gel, and better-optimized ITZs together yield higher compressive and tensile strengths.

High durability: The extremely low permeability makes it difficult for harmful substances (such as chloride ions and sulfates) to invade, significantly improving the concrete’s resistance to freeze-thaw, carbonation, and erosion, and extending the service life of the structure.

Low shrinkage: The optimized pore structure and hydration products help reduce drying and self-shrinkage.

Excellent crack resistance: The uniform structure and stronger bonding force reduce the risk of cracking.

polycarboxylate superplasticizer is not only a chemical additive that improves concrete workability, but also a key technology that fundamentally reshapes concrete’s microstructure. In today’s pursuit of high performance and sustainable development, a deep understanding of PCE’s impact on concrete microstructure is of immeasurable value for the research and development of new high-performance concrete and for promoting green transformation in the construction industry.

Super Early Strength Polycarboxylate Superplasticizer For Sleeve Grouting Material

Blog Super Early Strength