Blog

Polycarboxylate ether superplasticizer (PCE) have revolutionized the concrete industry, enabling the production of high-performance concrete with improved workability, strength, and durability. Its superior performance lies in its complex molecular mechanism, which combines electrostatic repulsion and spatial site resistance to achieve excellent dispersion of cement particles.

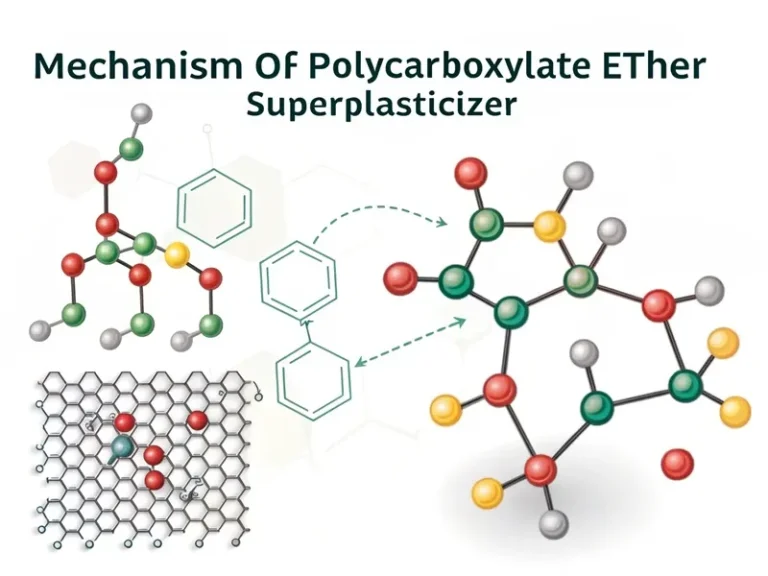

PCE is a comb-shaped polymer with a major polyether backbone and multiple side-chain carboxylates and ethers. This unique structure is the key to its performance.

Main chain: a polycarboxylate backbone containing negatively charged functional groups (e.g., -COOH, -SO3H) that provide spatial site resistance and aid in dispersion.

Side chains: long polyether chain segments (e.g., polyethylene glycol, PEG) attached to the main chain.

These side chains’ length, density, and chemical composition are critical to optimizing performance. Also, the length and density of the side chains can be customized to optimize performance for specific concrete applications.

Different lengths of side chains also have different functions.

Short side chains: enhance electrostatic repulsion but reduce spatial stability.

Long side chains: improve spatial site resistance but may increase water demand.

The mechanism of PCE, a highly efficient water-reducing agent, involves the combination of spatial site resistance and electrostatic repulsion, which can effectively disperse cement particles and improve the fluidity of concrete mixture.

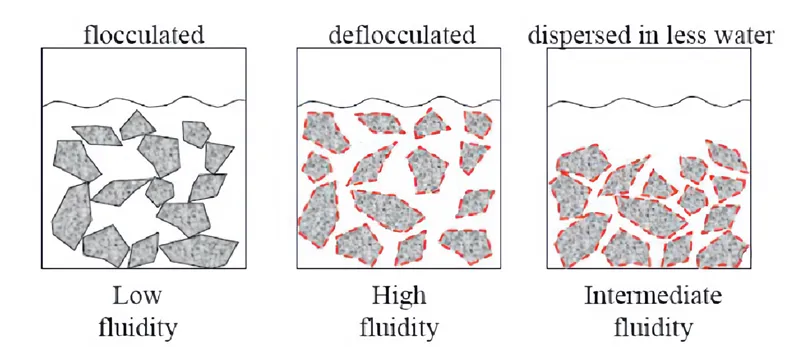

Charge interaction: when PCE is added to concrete, it forms a film with negative charges by adsorbing on the surface of cement particles. The electrostatic repulsion between these negative charges causes the cement particles to repel each other, thus preventing them from regrouping and maintaining the fluidity of the concrete.

Dispersion: The repulsive force between the charged particles prevents aggregation, separating the cement particles and releasing the entrained water.

Efficiency: This mechanism reduces the water-cement ratio by 20-40%, significantly improving strength and durability.

Physical barrier: hydrophilic polyether side chains extend into the aqueous phase and form a hydrated layer around the cement particles.

Stability: The layer acts as a spatial barrier and resists flocculation even during water evaporation or hydration.

Slump retention: The spatial barrier keeps the concrete fluid for a long time, which is crucial for complex pouring and long-distance transportation.

The combined effect of electrostatic repulsion and spatial site resistance leads to:

Enhanced workability: high initial fluidity and reduced viscosity.

Sustained performance: slump retention for 2-6 hours.

Strength development: lower water content leads to a denser microstructure and higher compressive strength (up to 30% increase).

Side chain length: longer chains can improve spatial stability but may reduce adsorption efficiency.

Charge density: The higher density of carboxylic acid groups increases electrostatic repulsion but may result in excessive water demand.

Aluminate content: High-aluminate cements (e.g., C3A) require PCE with a specific charge distribution to avoid rapid adsorption.

Mineral admixtures: Fly ash or slag may alter the PCE adsorption kinetics and require formulation adjustments.

Dosage: Typical dosage is 0.1-0.3% by weight of cement; excessive amounts can lead to air entrainment or separation.

Temperature: High temperatures accelerate hydration, requiring PCE to be thermally stable and have delayed adsorption properties.

Compatibility with other admixtures needs to be considered as interactions may occur.

The mechanism of polycarboxylate ether superplasticizer represents a triumph of polymer science in construction. By utilizing electrostatic repulsion and spatial site resistance, PCE transforms ordinary concrete into a high-performance material capable of meeting the demands of modern infrastructure.

As researchers refine molecular designs and engineers explore new applications, PCE redefines the boundaries of concrete technology, driving innovation toward safer, greener, smarter buildings.

For advanced PCE solutions tailored to your project, contact us today.

How Does Polycarboxylate Affect The Dyeing Process Of Textiles?

Blog How does Polycarboxy