Super Early Strength Polycarboxylate Superplasticizer For Sleeve Grouting Material

Blog Super Early Strength

Blog

Abstract: As one of the most widely used building materials in modern construction engineering, concrete’s workability and durability directly affect the quality, safety, and service life of the project.

Among concrete admixtures, polycarboxylate superplasticizer synthesized from TPEG 2400 stands out with its unique chemical structure and excellent performance characteristics, opening up new avenues for the dual improvement of concrete workability and durability.

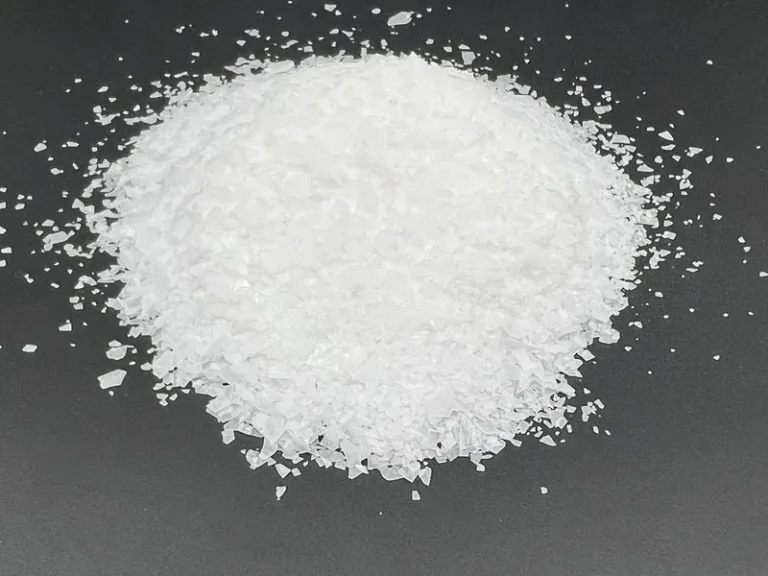

TPEG 2400, also known as isopentenol polyoxyethylene ether, is a vital polyether monomer. In its molecular structure, the isopentenyl group endows the molecule with specific reactivity. At the same time, the polyoxyethylene ether segment provides good water solubility and steric hindrance effects.

This unique structural combination enables TPEG 2400 to play a central role in the synthesis of polycarboxylate superplasticizers, laying a solid foundation for improving the performance of concrete.

The polyoxyethylene ether segments in TPEG 2400 molecules form an adsorption layer on the surface of cement particles, effectively preventing the agglomeration of cement particles through the steric hindrance effect.

The long-chain polyoxyethylene ether structure acts as a protective shield, allowing cement particles to be evenly dispersed in the concrete system, thereby significantly improving the fluidity of the concrete. During the concrete mixing process, cement particles can move more freely, making it easier for the concrete to reach the desired working state.

In an alkaline concrete environment, TPEG 2400 molecules partially ionize, generating charged groups that form electrostatic repulsion on the surface of cement particles. This electrostatic repulsion and steric hindrance effect work together to further enhance the dispersion effect of cement particles.

Cement particles repel each other, avoiding agglomeration and flocculation, maintaining the slump of concrete, reducing slump loss, and ensuring good workability of concrete during transportation and pouring

TPEG 2400 use for concrete can reduce the water-cement ratio, which is one of the essential mechanisms for improving its workability. Adsorbing and dispersing on the surface of cement particles enables free water in the concrete system to more effectively envelop the cement particles, thereby ensuring good fluidity of the concrete while reducing water consumption.

This means that using TPEG 2400 concrete can reduce the amount of water used, thereby improving the strength and durability of the concrete under the exact performance requirements.

Accurate regulation of water usage not only improves the workability of concrete but also has a positive impact on its strength development. The lower water-cement ratio makes the pore structure inside the concrete denser and the cement hydration reaction more complete, thereby improving the compressive and tensile strength indicators of the concrete.

In practical engineering, this characteristic enables concrete to achieve higher strength levels while meeting the workability requirements of construction, providing strong guarantees for the structural safety of buildings.

TPEG 2400 is compatible with other concrete admixtures, such as air-entraining agents and retarders. The composite admixture system can work synergistically with other admixtures to optimize the workability of concrete further.

For example, when used in conjunction with air-entraining agents, it can introduce uniformly distributed tiny bubbles into concrete, which can not only improve the fluidity of concrete but also enhance its frost resistance.

When combined with retarders, the setting time of concrete can be adjusted to meet the requirements of different construction processes and environmental conditions.

This good compatibility enables the polycarboxylate superplasticizer containing TPEG 2400 to adapt to various complex engineering requirements.

Whether it is concrete engineering that requires delaying the setting time in high-temperature environments, projects that require improving frost resistance in cold regions, or high-performance concrete engineering that has unique requirements for workability and strength, TPEG 2400 can provide suitable solutions through its synergistic effect with other additives to ensure that the workability of concrete meets engineering requirements.

The dispersing effect of TPEG 2400 in concrete helps optimize the pore structure of concrete. By uniformly dispersing cement particles, the formation of large pores and connected pores is reduced, and the proportion of tiny pores and gel pores is increased. These pores and gel pores can effectively prevent the penetration of water, harmful gases and ions and improve the impermeability of concrete.

In projects such as underground engineering and water conservancy engineering that require high impermeability of concrete, the use of concrete containing TPEG 2400 can effectively prevent groundwater leakage and protect the integrity of the structure.

The lower porosity also enables concrete to better resist the invasion of corrosive media from the outside. In marine engineering, concrete faces erosion from seawater, and harmful substances such as chloride ions and sulfates can easily penetrate into the interior of concrete, causing steel corrosion and structural damage.

TPEG 2400 reduces the porosity and channels for corrosive media to enter the interior of concrete, thereby enhancing the concrete’s resistance to corrosion from seawater and chemical solutions and extending the service life of concrete structures in harsh environments.

Alkali aggregate reaction is one of the critical factors affecting the durability of concrete. When alkaline substances in concrete (such as potassium hydroxide, sodium hydroxide, etc.) react chemically with active ingredients in aggregates (such as specific siliceous aggregates), expansive products are generated, leading to expansion stress inside the concrete and causing damage such as cracking and peeling.

This kind of damage not only reduces the strength and appearance quality of concrete but also seriously affects the safety and durability of concrete structures.

TPEG 2400 can inhibit the occurrence of alkali aggregate reactions. The polyoxyethylene ether segments in its molecular structure can undergo physical adsorption or chemical reactions with alkaline substances in concrete, reducing the contact opportunities between alkaline substances and aggregates, thereby reducing the activity of alkali aggregate reactions.

At the same time, the addition of TPEG 2400 can also improve the microstructure of concrete, increase its density, further enhance its resistance to alkali aggregate reactions, and protect the concrete structure from internal expansion stress damage.

Reinforcement is an essential load-bearing component in reinforced concrete structures, and its corrosion can lead to a reduction in the cross-section and strength of the reinforcement.

At the same time, the volume expansion of the corrosion products can cause cracking and peeling of the concrete protective layer, further accelerating the corrosion of the reinforcement and the damage to the concrete structure. Therefore, enhancing the corrosion resistance of steel bars is crucial for improving the durability of concrete structures.

TPEG 2400 effectively prevents the infiltration of external moisture, oxygen, and corrosive ions (such as chloride ions) into the interior of concrete by improving its density and impermeability, thereby providing a relatively stable alkaline environment for steel reinforcement and inhibiting its corrosion.

In addition, TPEG 2400 may also form a protective film on the surface of the steel bars, further isolating them from contact with corrosive substances from the outside world, slowing down the rate of steel bar corrosion, and extending the service life of reinforced concrete structures.

The Burj Khalifa is known as the “tallest building in the world,” with a height of 828 meters and a total of 162 floors. In order to build the Burj Khalifa, about 4000 workers and 100 cranes were mobilized to vertically pump concrete to a height of over 606 meters.

After using a polycarboxylate superplasticizer containing TPEG 2400, the workability of concrete was significantly improved. Its good fluidity and slump resistance enable concrete to be smoothly transported to high altitudes through the pumping system, avoiding construction problems such as pipe blockage.

HZM Bridge project is the longest sea-crossing bridge built in the world, with ultra-high standards in road design, service life, collision prevention, earthquake resistance, and flood and wind resistance. Due to long-term exposure to marine environments, concrete structures are affected by various factors such as seawater erosion, chloride ion infiltration, and wet-dry cycles.

By using TPEG 2400 as a key component of the admixture, the impermeability and erosion resistance of concrete have been significantly improved. After years of use, the concrete structures such as bridge piers and decks of the bridge remain in good condition, without severe corrosion or damage, proving the outstanding effect of TPEG 2400 in improving the durability of concrete.

TPEG 2400, as a high-performance polyether monomer, plays an irreplaceable role in improving workability and durability in the field of concrete. Through its unique dispersibility, precise control of water consumption, and good compatibility with other additives, the workability of concrete has been significantly improved, enabling it to better meet the requirements of various construction processes.

At the same time, by reducing porosity, inhibiting alkali aggregate reactions, and enhancing the corrosion resistance of steel bars, multiple methods have effectively improved the durability of concrete and extended the service life of concrete structures.

With the continuous development of construction engineering technology and the increasing demand for concrete performance, the application prospects of TPEG 2400 will be even broader. Future research can further optimize the synthesis process of TPEG 2400, reduce production costs, and improve the stability of product quality.

At the same time, we will conduct in-depth research on its composite application with new additives and high-performance aggregates and develop concrete formulas that are more suitable for complex environments and special engineering needs.

In addition, with the increasing awareness of environmental protection, creating more environmentally friendly and sustainable TPEG 2400 products will also become a future development trend, contributing to the green development of the construction industry.

Super Early Strength Polycarboxylate Superplasticizer For Sleeve Grouting Material

Blog Super Early Strength