Super Early Strength Polycarboxylate Superplasticizer For Sleeve Grouting Material

Blog Super Early Strength

Blog

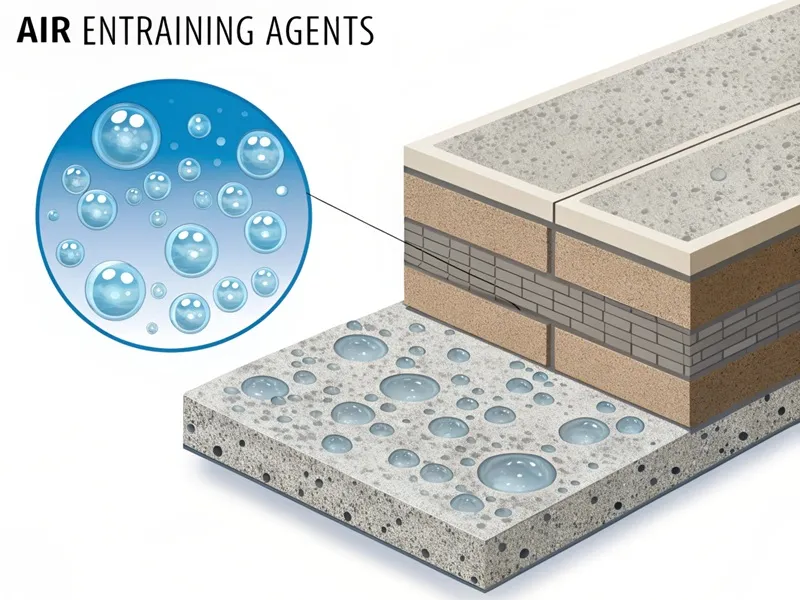

Air entraining agents (AEAs) are key chemical admixtures in concrete that can introduce microbubbles into the concrete, significantly improving its resistance to freeze-thaw cycles, deicing salts, and other durability challenges.

These reagents are typically composed of surface-active substances, such as synthetic detergents, fatty acids, or resin acids.

With the increasing demand for durability and elastic concrete structures, especially under harsh environmental conditions, the use of air-entraining agents is becoming more and more common.

The bubbles generated by these reagents are very small, typically ranging in diameter from 50 to 500 micrometers. They are evenly distributed in concrete, usually accounting for 2% to 8% of the total volume of concrete, depending on the specific requirements of the project.

Their working principle is to reduce the surface tension of water in concrete mixtures, allow air to mix in during the mixing process, and prevent bubble coalescence or collapse.

When an air-entraining agent is added to concrete, it will start to take effect once the mixing process begins. The surface active molecules of the reagent adhere to the air-water interface, forming a thin film around each bubble. This film provides stability for bubbles, preventing them from merging with each other and ensuring their dispersion in the concrete matrix.

This is one of the most widely used air entraining agents. It is mainly composed of sodium rosin, modified rosin thermal polymer, and rosin acid salt. The preparation method of rosin-based air entraining agents is simple, cost-effective, and has stable and reliable performance.

This type of air-entraining agent uses propylene as the raw material, polymerizes to obtain polypropylene, and then reacts with benzene to form a polymer of dodecyl benzene. Representative products are sodium dodecyl benzene sulfonate and sodium dodecyl sulfate. Although its bubble effect is slightly insufficient, it can still adsorb solid particles in water and generate bubbles.

This type of air-entraining agent has excellent foaming and stability, which can effectively improve the workability of concrete and enhance its frost resistance and durability. However, its cost is relatively high.

In cold weather conditions, when the water in the pores of concrete freezes, it will expand by about 9%. If this expansion is not properly adapted, the resulting pressure may cause concrete to crack, peel off, and ultimately deteriorate.

The bubbles introduced by the air-entraining agent provide necessary void space for the expanding water during the freezing process. When water turns into ice, it can expand into these air pockets, releasing the internal pressure inside the concrete. This mechanism significantly reduces the risk of cracking and damage, thereby extending the lifespan of concrete structures.

For example, in areas with severe winter temperatures, roads, bridges, and other concrete infrastructure using air-entraining concrete can withstand decades of repeated freeze-thaw cycles without significant degradation.

Air entraining agents can also improve the workability of concrete. The presence of bubbles in concrete mixtures acts as a lubricant, reducing internal friction between aggregate particles and cement slurry. This makes concrete more fluid and easier to handle during the pouring, compaction, and finishing processes.

By improving workability, construction workers can more easily pour concrete into complex templates, ensuring better filling of the templates and reducing the need for excessive vibration. No additional water is needed to increase fluidity by 10-15%.

In areas where deicing salt is used on roads and bridges during winter, concrete is subject to chemical erosion in addition to freeze-thaw cycles. Chloride ions in deicing salt can penetrate into concrete, causing corrosion of steel bars and resulting in structural damage.

Aerated concrete has better resistance to deicing salts. The void system generated by the air-entraining agent destroys the capillary pores in the concrete, making it more difficult for chloride ions to penetrate.

In addition, the improvement of durability of air-entraining concrete reduces the possibility of surface scaling and peeling caused by the combined action of salt and freezing, further protecting the overall integrity of the underlying steel and structure.

The type of air-entraining agent used has a significant impact on its performance. Different reagents may have varying degrees of effectiveness in generating and stabilizing bubbles, as well as different compatibility with other components of concrete mixtures such as cement and aggregates.

A low dosage of air entraining agent may not introduce enough air to provide sufficient protection against freeze-thaw cycles or other forms of damage. On the contrary, excessive dosage can lead to a decrease in concrete strength, as too many bubbles weaken the concrete matrix. The optimal dosage is usually determined through laboratory testing, depending on factors such as cement type, aggregate properties, and required air content.

The ratio of cement, water, and aggregate in concrete mixtures can affect the performance of air-entraining agents. A higher water-cement ratio may require a higher dosage of reagents to achieve the desired air content.

In addition, the type and grading of aggregates can affect how air-entraining agents distribute bubbles in concrete. Compared to fine and smooth aggregates, coarse aggregates with rough texture may require more additives to achieve the same air-entraining effect.

The mixing process plays a crucial role in the effectiveness of the air-entraining agent. Adequate mixing time is necessary to ensure uniform distribution of reagents in the concrete and correct formation and stability of bubbles.

Excessive or insufficient mixing can lead to inconsistent air content and poor performance. It is crucial to follow the recommended mixing program and device settings for optimal results.

Roads and highways: In cold climates, air-entraining concrete is used to construct roads, runways, and airport taxiways. Enhanced resistance to freeze-thaw cycles and deicing salts helps maintain surface integrity, reduces the need for frequent maintenance, and extends the service life of infrastructure.

Bridges and overpasses: Bridges are often exposed to adverse weather conditions, including freeze-thaw cycles and the effects of deicing salts. Air-entraining concrete is used for bridge decks, piers, and abutments to ensure long-term durability and structural stability.

Buildings in cold climates: For buildings in cold regions, air-entraining concrete is used for foundations, walls, and floors. It helps protect the structure from the destructive effects of freezing and thawing, as well as chemical erosion from deicing salts used on surrounding roads and sidewalks.

Marine ports and offshore platforms: Resistant to seawater corrosion and tidal wear.

It has been proven that air-entraining agents are indispensable in modern concrete construction. They can improve the durability, workability, and performance of concrete, making it a valuable additive in concrete mixtures, especially in challenging environments.

With the increasing demand for sustainable and high-performance buildings, the role of air-entraining agents in concrete technology will only become more important in the future.

Super Early Strength Polycarboxylate Superplasticizer For Sleeve Grouting Material

Blog Super Early Strength