Blog

Superplasticizers play a crucial role in various concrete applications in the construction industry. Their unique performance and capabilities have entirely changed how concrete is used, making constructing more complex, durable, high-performance structures possible.

Transporting concrete to considerable heights is a significant challenge in high-rise building projects. In this regard, superplasticizers play a vital role as they enhance the fluidity of concrete, allowing it to be smoothly pumped through long and vertical pipelines.

The superplasticizer effect of high-efficiency water-reducing agents reduces the water-cement ratio while maintaining workability. This makes the concrete mixture more viscous and fluid, allowing it to reach the upper layer without segregation or blockage.

For example, when constructing a 50-story skyscraper, polycarboxylate Superplasticizers can ensure that concrete can be effectively pumped to the top floor, thereby achieving continuous construction and maintaining the quality of the concrete structure.

High-rise buildings must withstand significant vertical loads, wind force, and seismic activity. Superplasticizer promotes the formation of a denser concrete matrix by reducing the water-cement ratio. This denser structure improves the compressive strength of concrete and enhances its crack resistance under stress.

The enhanced durability provided by high-efficiency water-reducing agents can also protect buildings from environmental factors such as weathering and chemical exposure, ensuring the long-term stability of high-rise buildings.

Bridges, especially large-span and large bridges, require a lot of concrete to be poured. Superplasticizers play a crucial role in this process. They improve the workability of concrete, making it easier to place and compact in large-volume applications such as bridge piers and decks.

When concrete pouring is carried out in multiple stages or over long distances, the ability of superplasticizers to maintain slump is particularly beneficial. This ensures that the concrete remains constructible throughout the pouring process, reduces the risk of cold joints, and provides uniformity of the structure.

For example, in constructing large-span suspension bridges, high-efficiency water-reducing agents help seamlessly pour concrete into the central piers, which typically have a diameter of several meters and require a large amount of concrete.

Bridges are exposed to harsh environments, including traffic loads, temperature changes, moisture, and chemical exposure to de-icing salts. Superplasticizer is used to improve the durability of bridge concrete. They reduce the permeability of concrete and prevent water, chloride ions, and other harmful substances from entering. This is crucial for preventing corrosion of steel bars within bridge structures.

In addition, the enhanced resistance to chemical erosion provided by high-efficiency water-reducing agents helps bridges withstand the impact of environmental pollutants and industrial emissions. Therefore, high-efficiency water-reducing agents can help extend the long-term service life of bridges, reduce maintenance costs, and ensure the travelling public’s safety.

The ability to achieve early strength development is crucial in the production of precast concrete. Superplasticizers, especially melamine formaldehyde-based superplasticizers, are highly effective in promoting rapid strength growth. By reducing the water-cement ratio and enhancing the dispersibility of cement particles, they accelerate the hydration process of cement. This enables prefabricated components such as beams, columns, and panels to obtain sufficient strength quickly.

For example, in precast concrete factories, superplasticizers can de-mould prefabricated components within one or two days compared to longer curing times without superplasticizers. This dramatically improves the factory’s production efficiency, as more prefabricated components can be produced within a given time frame.

Superplasticizer helps achieve consistent quality of precast concrete products. They ensure that cement particles are more evenly dispersed in the concrete mixture, forming a uniform microstructure. This improves the dimensional accuracy and surface smoothness of prefabricated components.

The consistent quality of prefabricated products is crucial for their correct on-site assembly. When prefabricated components are used in construction, their precise dimensions and good surface finish ensure a tight fit and appropriate load transfer between the elements. This improves the building’s structural performance and enhances its aesthetic appeal.

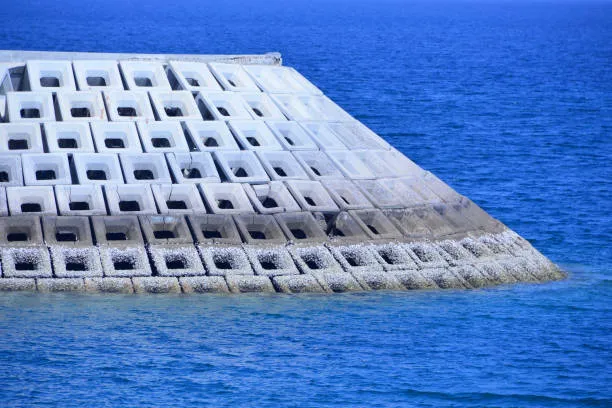

Marine and coastal buildings are often exposed to seawater containing high chloride ions. These ions can penetrate concrete, corrode steel bars, and cause structural degradation.

By using superplasticizers, concrete’s porosity is reduced, making it difficult for chloride ions to penetrate. This significantly reduces the corrosion risk caused by chlorides and extends the service life of marine structures such as docks, breakwaters, and seawalls. For example, concrete structures reinforced with superplasticizers in coastal ports can withstand seawater’s corrosive effects for decades without causing significant damage.

In addition to corrosion caused by chlorides, marine and coastal structures face other harsh environmental conditions, such as high humidity, strong winds, and wave action. Superplasticizer improves the overall durability of concrete, making it more resistant to these conditions.

Due to the use of superplasticizers, the strength and toughness of concrete have been enhanced, enabling the structure to withstand the mechanical forces exerted by waves and wind. Improving resistance to chemical erosion from seawater and other environmental factors also helps the structure maintain its integrity over time.

Industrial flooring and road surfaces are susceptible to traffic congestion, wear and tear, and chemical spills. Superplasticizer is used to produce concrete with high strength and wear resistance. By reducing the water-cement ratio, they created a denser concrete surface that can withstand continuous friction and mechanical stress in industrial vehicles and equipment.

For example, concrete treated with superplasticizers in factory workshops can resist wear and tear caused by forklifts and heavy machinery, thereby reducing the need for frequent maintenance and replacement.

Industrial environments typically involve exposure to various chemical substances. Superplasticizers can improve the chemical resistance of concrete floors and pavements. The denser structure of concrete achieved through the use of superplasticizers provides better chemical corrosion protection.

Concrete can maintain its integrity and functionality despite exposure to acid, alkali, or other industrial chemicals. This is particularly important in chemical plants, food processing facilities, and refineries, where chemical spills often occur.

In short, superplasticizers are a universal and essential additive in the construction industry. They have many applications, from high-rise buildings and bridges to precast concrete production, marine structures, and industrial flooring.

Superplasticizers can build more sustainable, efficient, and long-lasting structures by improving processability, enhancing strength, and increasing durability. With the construction industry’s continuous development, superplasticizers may become more widespread, promoting innovation and progress in the concrete construction field.

What are the safety precautions for operating polycarboxylate superplasticizers?

Blog What are the safety